Add: North Area of New & Hi-tech Park, Pingxiang City, Jiangxi Prov, China.

Tel:

+86 13387997914,

+86 799 3671932

Fax: +86 799-3671922

Postcode: 337000

Website: www.siton-china.com

Introduction of DT1-14D Big Slope Drilling Jumbo:

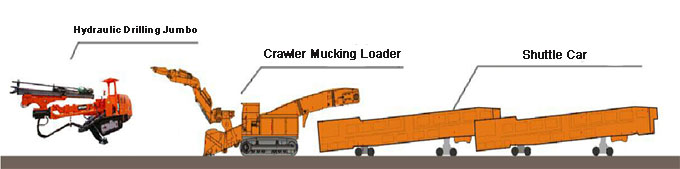

Hydraulic single boom underground jumbo is equipment for drilling tunnels and mines. Combined with borehole and blasting, DT1-14D tunnel jumbo drill machines can cooperate well with muck loaders and realize high working efficiency. At the same time, working condition for workers is greatly improved. This jumbo is constituted by drill boom, rock drill, hydraulic system, and so on.

1. Hydraulic Drill Boom

Drill boom of hydraulic single boom underground jumbo is improved in location accuracy and speed, which greatly increases working efficiency.

(1) Separation distance between blastholes is designed to meet higher precision and parallelism.

(2) Telescopic boom can enlarge drilling scale which is beyond drilling scale of single boom.

(3) In the tunnel jumbo drill machine, cross-section of main boom is quadrate, which makes the drill boom more stable in bearing stress. Besides, main boom applies rotary motor as power system and can rotate within 180°.

2. Rock Drill

(1) DT1-14D hydraulic single boom underground jumbo employs rock drill produced by Montabert SAS. This Rock drill works on rocks whose maximum hardness reaches up to 15.

(2) Its drilling efficiency is 2 to 4 times that of traditional drills.

(3) Hydraulic compensation can avoid failures in drilling. Besides, drill shank is designed to eliminate reactive force caused by impact, which makes rock drill durable.

3. Hydraulic System

(1) The oil tank is located over the oil pump. Unlike the old tunnel jumbo drill machine, oil pump of DT1-14D jumbo is free of cavitation erosion because of oil lack.

(2) In hydraulic single boom underground jumbo, multiple oil filtering system increases oil purity and decreases malfunction of hydraulic system.

(3) Reasonable oil flow in pumps as well as efficient water cooler can guarantee suitable oil temperature even after long-time working.

(4) Hydraulic pressure is increased gradually, which makes boosting force and impact force perfectly transferred. Hence, drilling location is more accurate and drilling efficiency is increased.

(5) Manual controlling handle is employed to make operation more comfortable.

4. Standard Configurations

DT1-14D hydraulic single boom underground jumbos are equipped with high-power work light, hydraulic air compressor and lift safety ceiling (passed FOPS).

5. Optional Configurations

Hydraulic pump and large/small-power diesel engine are optional for tunnel jumbo drill machines.

| Drilling Speed | 0.8 - 2 m/min |

| Drill Boom Length | 3090 mm |

| Drilling Hole Diameter | Φ28 mm - Φ102 mm |

| Hole Depth | 2700 mm |

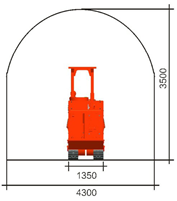

| Excavation Face (Width × Height) | ≤4.3 m × 3.5 m |

| Travel Speed | 10 m/min |

| Gradeability | ≤26° |

| Creeper Tread Width | 270 mm |

| Rock Drill | 1 × HYD200 |

| 1 × HC25/HC50 (Montebert Optional) | |

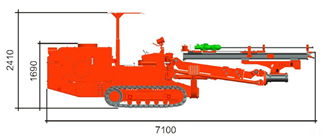

| Dimension (Length × Width × Height) | 7100 × 950 × 1690 mm 2410 mm (Height of Ceiling) |

| Weight | 7600 kg |

| Total Power | 39.2 kw |

| Motor Power | 37 kw |

| Voltage | 380-1140 (V) |

| Frequency | 50-60 (Hz) |

| Main Hydraulic pump (Standard /Advanced) | 3 × Gear Pump (Standard) |

| 1 × Plunger Pump +1 × Gear Pump (Advanced) | |

| Max. Working Pressure | 20 Mpa |

| Oil Tank Capacity | 240 L |

| Cooling Medium | Water |

| Operation Panel | 1 |

| Boom Quality | 1 |

| Compensation | 1500 mm |

| Drilling Way | Mechanically Translational Motion |

| Rotation | ± 180° |

| Boom Swing Scale | ± 32° |

| Lifting Scale | +45°/ -15° |

| Pitching Up/Down | 35 +16/10° |